FL -300 Pharmaceutical Granulator Fluid Bed Dryer For Pellet And Pills

Product Details:

| Place of Origin: | China Origin |

| Brand Name: | HSD |

| Certification: | CE/SGS/UL/ISO |

| Model Number: | FL-300 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | USD 15000-35000 |

| Packaging Details: | Standard exported wooden case for long and safe sea shipping |

| Delivery Time: | 45 working days |

| Payment Terms: | T/T, L/C |

| Supply Ability: | 100 pieces per year |

|

Detail Information |

|||

| Material: | SS304, SS316L | Safety: | GMP, Reliable Safety Device |

|---|---|---|---|

| Polish: | Ra0.8, Ra1.6, No Dead Corner | Cleaning: | Easy For Cleaning And CIP |

| Handle: | Easy For Workers To Handle | Control: | Smart Control And Big Touch Screen |

Product Description

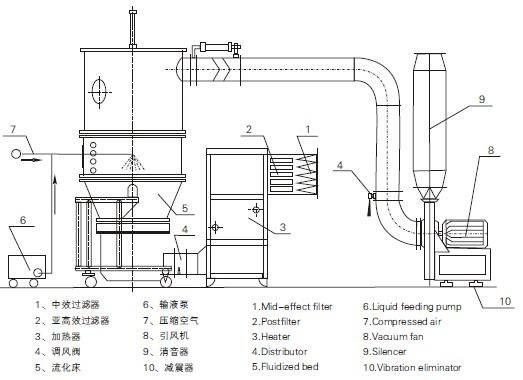

FL-300 ONE STEP FLUID BED GRANULATOR

Application

FL fluid bed granulator is a good choice for making particles, mixing powder, and drying processes

in pharmaceutical, food, feed, and chemical industry. This equipment complies with the state standard

GB12254-90. The particles are used as instant drink granules and for filling capsules or compressing

tablets.

Work Principle

Drying

Purify the air after heating and dehumidification.And the air pass through the distribution plate at the

bottom of the fluidized bed to dry the material quickly and gently.

The top spray granulating

Powder material and the top spray adhesive or the Chinese herbal extract is assembled into frains by the

liquid bridge, and are dried in same equipment, so it is also called one-step granulation.

Bottom spray coating

Bottom spray coating system is mainly applied to the film coating of pellets, powders, seeds, granules,

crystals and small tablets.

Cutting and spraying pill-making coating

Cutting and spraying pill-making coating system is used for making pellets, powder coating, making

solid granules, film coating and other processes.

Features

1.Sophisticated spray nozzle design

2.Shorter time of agglomeration

3.Dust- free closed system

4Two separate filter-shaking system

5.Continuous spray process

6.Measure up GMP standards

Technical Parameters

| FL Main parameter (as reference) | |||||||||

| Specification | Model | ||||||||

| Specification | Denomination | 15 | 30 | 60 | 120 | 200 | 300 | 500 | |

| Material Container | Volume | L | 45 | 100 | 220 | 420 | 670 | 1000 | 1500 |

| Dimension | mm | 550 | 700 | 1000 | 1200 | 1400 | 16000 | 1800 | |

| Capacity | Kg/batch | 15 | 30 | 60 | 120 | 200 | 300 | 500 | |

| Steam | Pressure | Mpa | 0.4--0.6 | ||||||

| Steam flow | Kg/h | 20 | 60 | 120 | 140 | 180 | 310 | 400 | |

| Compression air | Pressure | Mpa | 0.4-0.6 | ||||||

| Steam flow | m3/min | 0.6 | 0.6 | 0.9 | 0.9 | 1.1 | 1.1 | 1.5 | |

| Blower | Kw | 3 | 5.5 | 11 | 18.5 | 22 | 30 | 45 | |

| Heater | Kw | 12 | 21 | 30 | 48 | 87 | 163 | 185 | |

| Noise | db | less than 75 db | |||||||

| Tower Dimension (mm) | A | 1900 | 2100 | 2250 | 2650 | 2800 | 3500 | 4000 | |

| B | 1350 | 1800 | 2400 | 3200 | 3800 | 4200 | 4200 | ||

| C | 380 | 420 | 480 | 500 | 520 | 600 | 680 | ||

| D | 700 | 1100 | 1320 | 1420 | 1640 | 2000 | 2260 | ||

| E | 700 | 860 | 1000 | 1200 | 1400 | 1600 | 1800 | ||

Machine parts pictures

![]()

![]()

![]()

![]()

Shipping and Delivery

![]()

Raw Material

![]()

![]()

Machine quality inspection before leaving factory

![]()

Previous Exhibition

![]()

![]()

Service Flow

![]()

pre-sale service

We Invite customers to visit our company and communicate on technical requirements face to face.

sale service

Responsible for debugging the equipment according to customers' requirements of various technical data. Our engineers will train our customers about equipment features and operation key points to make sure the equipment running in the best condition.

after-sale service

We provide installation, debugging, maintenance, training and other services; Provide relevant technical data, equipment, software and related GMP certification materials;Set up after-sales service hotline, and arrange personnel to visit customers every year to know more customer needs,like customer operation problems in the process of production equipment.

quality promise

Our company promises strictly operate the ISO9001 quality system certification standards and pharmaceutical equipment GMP audit requirements,promise we provide new equipment. Advanced technology,good quality.Equipment operation safe reliable, affordable, easy to maintain.

Equipment warranty period is one year,all the parts for the equipment choose well-known brand.During the warranty when equipment have problem in quality like equipment failure and damage,the company for free maintenance or replacement.

Why choose us

1.Specialized in designing, developing and manufacturing.

2.Above 130 National patents,national and provincial technology innovation awards

3.Provincial Pharma Equipment Engineering Technology Research Center

4.National High-Tech,National Pharma Equipment Industry Association,Provincial new special expertise Enterprises

5.Manufacture the solid preparation production line equipment for above 500 domestic and oversea enterprises

6.Modern production workshop and production line of high-end manufacturing equipment

7.Professional and efficient after-sales service management

8.Competitive price and prompt delivery

9.Meet ISO9001 and CE

10.OEM/ODM available

Company View

Company introduction: Changzhou Hansheng Drying Equipment Co., Ltd.

Changzhou Hansheng Drying Equipment Co.,Ltd has established in 2011 and it covers an area of 15000 square meters, possesses fixed asset of USD 5 million. The products have exported to US, Singapore, India, Ukraine, Russia, Korea and so on. The company have advanced production equipment , excellent technical team and after-sales service.

![]()

FAQ:

1. Q: Please describe your warranty period.

A: 15 months after the equipment is arrived at the destination port or 12 months after the installation and commissioning of the equipment, whichever comes first.

2. Q: Do you provide on-site installation and commissioning?

A: Yes, we do. If on request, we'll provide the guidance of on-site installation and commissioning. Usually one mechanical engineer and one electrical engineer to assist.

3. Q: How about the cost of on-site installation and commissioning guidance?

A: The cost consists of round-trip air tickets, room and board expenses, service cost (labor cost), and site transportation (or directly provided by client), which shall be paid additionally.

4. Q: Are you a factory or a trading company?

A: We are a professional manufacturer. We have own factory and pilot plant for customers to do sample testing.